We combine the latest technology and the experience of traditional jewellery making in our process

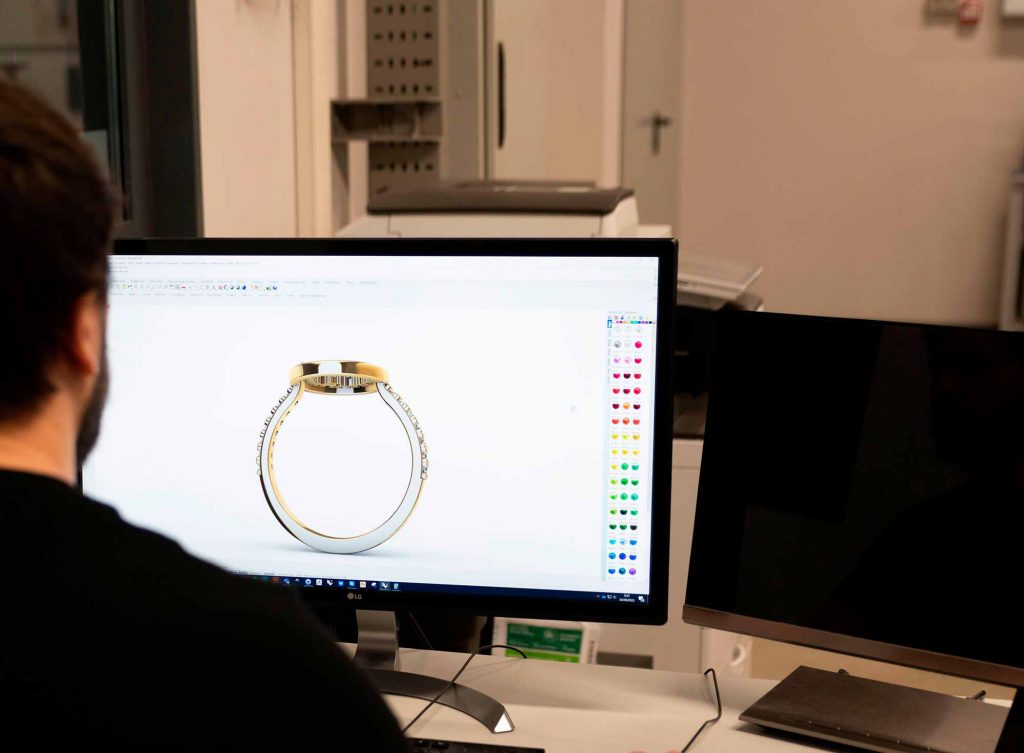

We work with the most innovative and leading technology in next generation software applied to the sector: Rhinoceros, Matrix, Rhinogold.Z-brush and render engines such as Vray and Keyshot.

We use state-of-the-art 3D prototyping equipment such as EnvisionTec, 3D System and Fomlabs. These machines allow the use of different types of materials according to needs, such as castable resins for cast iron and ceramic resins for the creation of vulcanizable molds.

We maintain the manual jewellery tradition applied to processes in which the expert hand of the jeweler craftsman is essential.

We upgraded micro melting by improving and automating the injection, micro crimping and casting processes.

We use state-of-the-art 3D prototyping equipment such as EnvisonTec, 3D System and Fomlabs.

These machines allow the use of different types of materials according to the needs, such as calcinable resins for casting and ceramic resins for the creation of vulcanizable molds.

We maintain the handmade jewelry tradition applied to processes in which the expert hand of the jeweler craftsman is essential.

We have a new automated polishing and grinding line.

In addition, we continue to use traditional hand polishing processes depending on the type of product or customer needs.

We renew and improve the process by acquiring state-of-the-art equipment.

We renew and improve the process by acquiring state-of-the-art equipment.

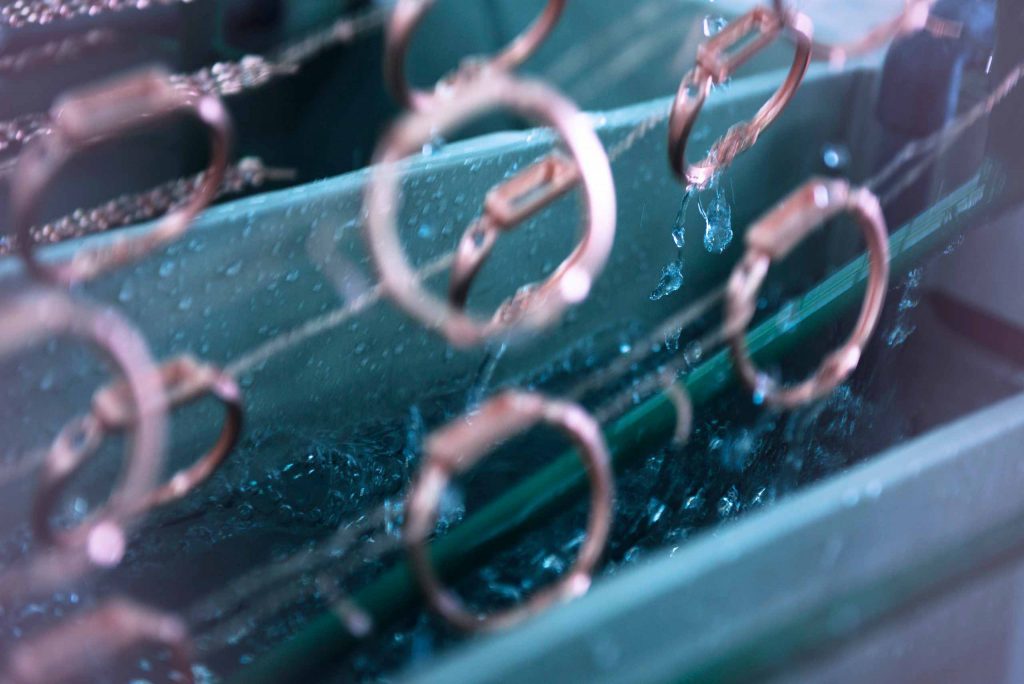

The galvanic process we use in the coating of our parts allows us to adapt to a wide variety of low and high thickness finishes in precious metals such as gold, silver and rhodium.

We also work with different surface coatings of cataphoretic and passivated lacquers.

With all this, quality and compliance with European and international standards is guaranteed.

For the production of our jewellery, we have a wide variety of materials available:

Brass, bronze and low fusion with different galvanic finishes.

Sterling silver jewellery with silver, rhodium and gold plated finishes.

18K gold jewellery set with diamonds, precious, semi-precious and synthetic stones.

Guaranteeing the highest quality of each of our jewels is a priority for Sikno. For this reason, we carry out two types of controls that certify this excellence:

Internal controls: all our pieces are subjected to restrictive tests where they must pass sweat tests, wear and tear, physical testing and thickness analysis, as well as precious metal concentrations through X-rays.

External controls: all processes are audited by external partners such as SGS, which guarantees the non-use of harmful and polluting materials in the manufacture of jewellery, or ECOMEP, which certifies that all our silver and gold jewellery complies with the precious metals regulation.