SIKNO marks the beginning of a new era in jewellery design and production. After almost 40 years dedicated to production, Sikno gathers all this experience and tradition in jewellery and combines it with an innovative and highly technological vision to expand its service to the sector and become its supplier par excellence.

With a 100% Spanish product, Sikno currently has the most advanced factory in Europe dedicated exclusively to supplying products to brands, wholesalers, chain stores, online sales operators, etc., and never to end customers. Among the factory’s differential values is its proximity. To avoid all the problems involved in importing products (travel, payments in advance, overflowing stocks, dubious quality controls …).

Sikno wants to become the great factory for European brands and we have all the elements for this. That is why expert professionals in the sector and large fashion firms are already with us.

How do we work?

PRODUCT DESIGN:

We work with the most innovative and cutting-edge 3D CAD design technology applied to the sector (Rhinoceros, Matrix, Rhinogoal, Z-brush and rendering engines such as Vray and Keyshot) and we use the latest generation 3D prototyping equipment such as Envison Tec, 3D System and Fomlabs. But we also maintain the hand-made jewellery tradition applied to those processes in which the craftsman’s expert hand is essential.

JEWELLERY DEVELOPMENT

We upgrade micro fusion by improving and automating the processes of wax injection, micro-setting, assembly and casting.

SURFACE TREATMENTS

We have a new automated polishing and grinding line. We also continue to use traditional hand polishing processes depending on the type of product or customer needs.

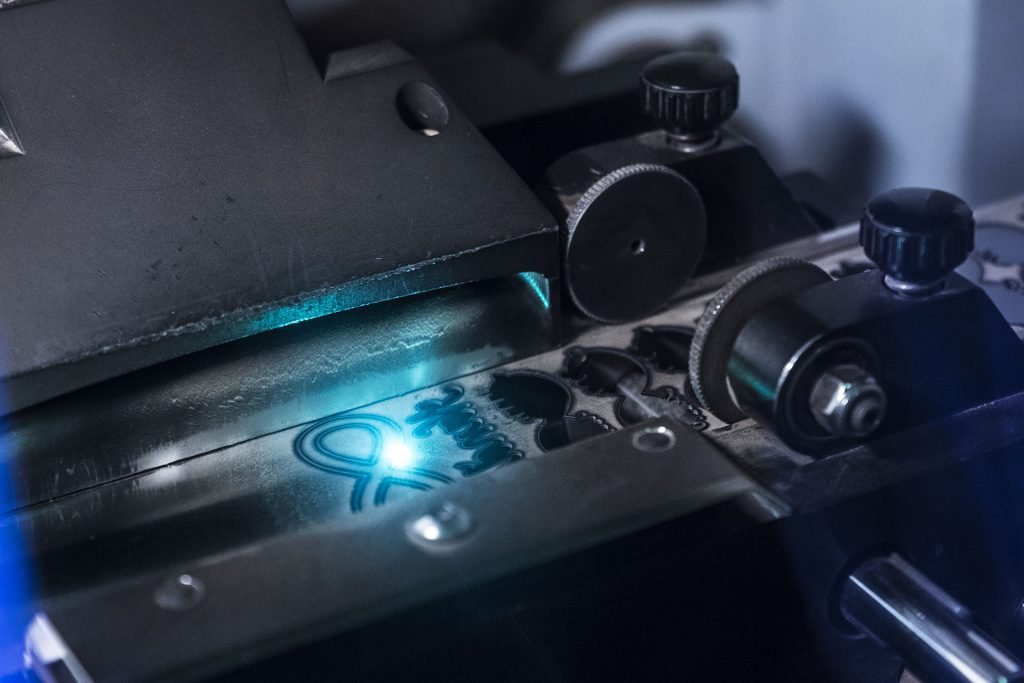

LASER CUTTING

We renew and improve the process by acquiring state-of-the-art equipment.

PRODUCTIVE CAPACITY AND AGILITY

We currently have a capacity for over 10 million units per year with a maximum delivery time of three weeks, depending on the type of product.

FLEXIBILITY

Our production process allows us to adapt to customer needs, both in quantities and in delivery times. We have a purchasing department that supplies us with raw materials and carries out the search for ad hoc material. Our partners include renowned companies such as Swarovski, SempsaJP, Italpreziosi, Legor…

NATIONAL PRODUCTION

Our hallmark of quality is agility in service, customer service and after-sales service, which denotes production carried out entirely in Spain.

COSTS WITHOUT COMPETITION:

The continuous effort to innovate and to have the most cutting-edge technological equipment has allowed us to achieve greater cost competitiveness.

ENVIRONMENTAL RESPONSIBILITY

We maintain a firm commitment to the environment. Therefore, our processes are optimized to generate the least possible impact on the environment, carrying out sustainable and nature-friendly production procedures. Proof of this is the ISO 9001 ER-0249 / 2017- 002/00 certification.

WHAT ARE YOUR DIFFERENTIAL VALUES?

We are specialists in B2B service, from business to business

CUSTOMISED

Customised jewellery is a clear trend in the market. For this reason, we have updated the manufacture of these products by introducing technological improvements that allow us to manufacture jewellery piece by piece and with maximum delivery times of 72 hours.

LASER WELDING

Together with the best partners in the sector, we develop specific equipment that allows us to offer more competitive and higher quality products.

GALVANOTECHNICS

The galvanic process that we use in the coating of our pieces allows us to adapt to a wide variety of low and high thickness finishes in precious metals. We also work with different surface coatings of cataphoretic and passivated lacquers. With all of this, quality and compliance with European and international regulations are ensured.

FINISHES

For the production of our jewellery, we have a wide variety of materials available:

- Brass, bronze and low fusion with different galvanic finishes.

- Sterling silver jewellery finished in silver, rhodium and plated in yellow and rose gold.

- 18k gold jewellery set with diamonds, precious, semi-precious and synthetic stones.

QUALITY CONTROL

Ensuring the highest quality for our jewellery is a priority for SIKNO. That is why we carry out exhaustive internal and external controls. All of our pieces are subject to restrictive tests where they must pass sweat tests, wear and tear tests, physical testing and thickness analysis, as well as concentrations of precious metals through X-rays. Furthermore, all processes are audited by external partners such as SGS, which guarantee the non-use of harmful and polluting materials in the manufacture of jewellery, or ECOMEP, which certifies that all our silver and gold jewellery complies with the precious metals regulations.